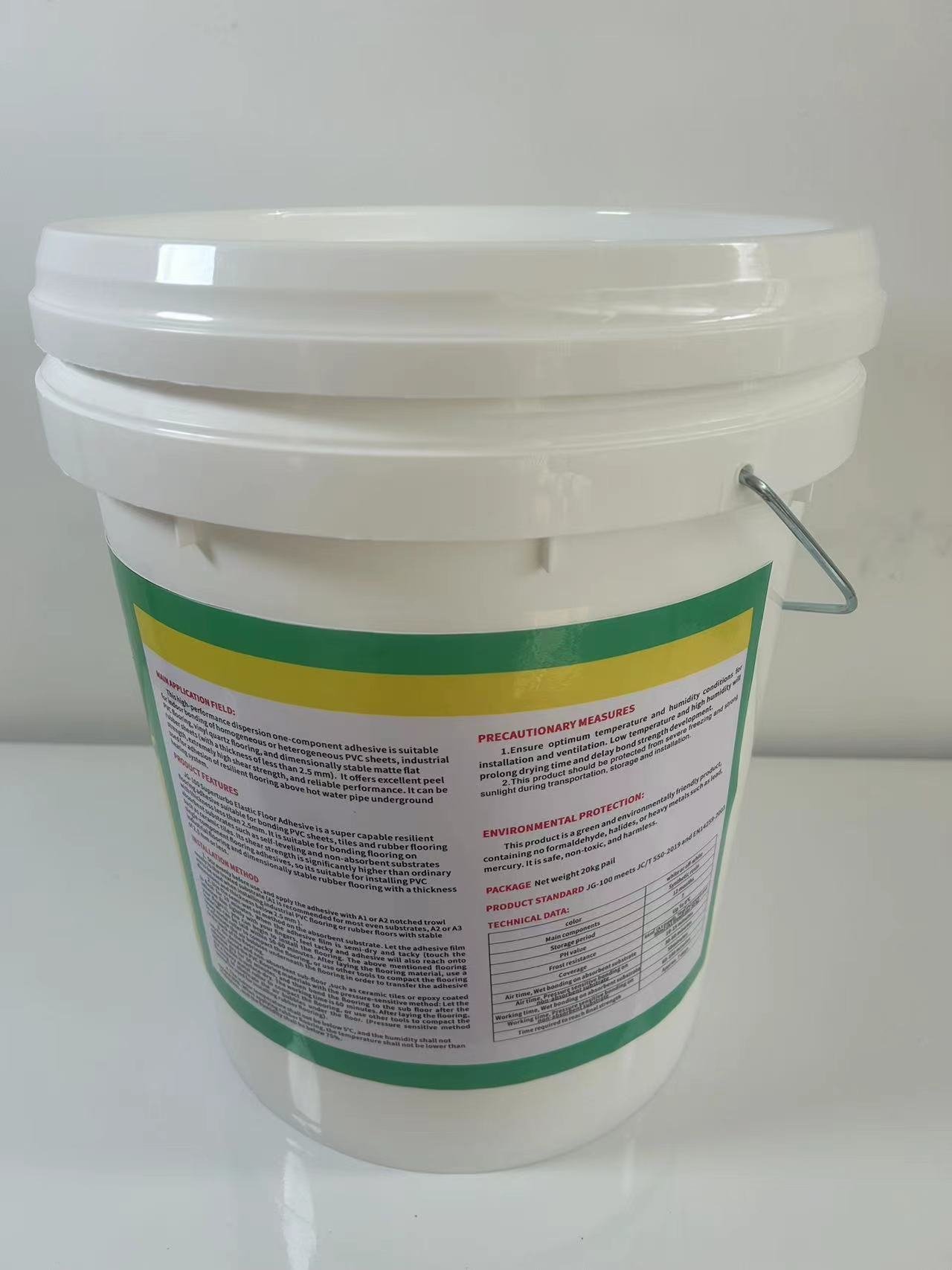

TECHNICAL DATA:

| color | White or off-white |

|---|---|

| Main components | Synthetic resin |

| Storage period | 12 months |

| PH value | 7 |

| Frost resistance | Up To 0℃ |

| Coverage | 66㎡(A3 trowel), 70㎡(A2 trowel) and 80㎡(A1 trowel) per/20kg |

| Air time, Wet bonding on absorbent substrate | 10-15 minutes |

| Air time, Pressure sensitive bonding on non-absorbent substrate | 30-60 minutes |

| Working time, Wet bonding on absorbent substrate | 50 minutes |

| Working time, Pressure sensitive bonding on non-absorbent substrate | 60-100 minutes |

| Time required to reach final strength | Approx. 7 days |

Package

Net weight 20kg pail

Product Standard

JG-100 meets JC/T 550-2019 and EN14259-2003

Installation method

- Stir evenly before use, and apply the adhesive with A1 or A2 notched trowel evenly to the treated substrate (A1 is recommended for vinyl flooring on even substrates, A2 or A3 are to be used when installing industrial PVC flooring or rubber floors with stable dimensions and thickness below 2.5 mm ).

- Use the semi-wetsetmethod on the absorbent substrate. Let the adhesive film to flash for 10 minutes. When the adhesive film is semi-dry and tacky (touch the adhesive film lightly with your fingers, feel tacky and adhesive will also reach onto your fingers), you can begin to install the flooring. The above mentioned flooring materials can be laid within 50-60 minutes. After laying the flooring material, use a heavy metal roller to compact the flooring, or use other tools to compact the flooring to eliminate the air bubbles underneath the flooring in order to transfer the adhesive to the back of the flooring.

- On denseandnon-absorbent sub-floor ,such as ceramic tiles or epoxy coated sub-floor, bond the PVC flooring materials with the pressure-sensitive method: Let the adhesive dry for 60 minutes, and then bond the flooring to the sub-floor after the adhesive film is surface-dry. The working time is 60 minutes. After laying the flooring, use a heavy metal roller to compact the flooring, or use other tools to compact the flooring to eliminate the air bubbles under the floor. (Pressure sensitive method cannot be used for installing rubber flooring).

4.The indoor temperature shall not be below 5℃, and the humidity shall not exceed 80%. When applying rubber flooring, the temperature shall not be lower than 15 degrees, and the humidity shall be below 75%.

Precautionary Measures:

- Ensure optimum temperature and humidity conditions for installation and ventilation. Low temperature and high humidity will prolong drying time and delay bond strength development.

- This product should be protected from severe freezing and strong sunlight during transportation, storage and installation.

Environmental Protection:

This product is a green and environmentally friendly product, containing no formaldehyde, halide, or heavy metals such as lead, mercury. It is safe, non-toxic, and harmless.

Reviews

There are no reviews yet.